E-Coat Oven Upgrade

Our customer approached us about their industrial ovens at their automotive paint-drying plant. We were asked to replace their heat exchange system to support their aims to increase their energy...

Welcome to Comtherm's blog on Industrial Combustion. Here, you'll find a curated collection of articles designed to deepen your understanding of burner technology and its applications in industrial settings. Whether you're an engineer, decision-maker, or simply interested in the field, our blogs offer valuable insights into the efficiency, safety, and innovation that drive industrial combustion processes.

Our customer approached us about their industrial ovens at their automotive paint-drying plant. We were asked to replace their heat exchange system to support their aims to increase their energy...

A major industrial facility specializing in the food industry approached us to improve the efficiency of their heat exchanger system. The existing burners were outdated and inefficient, leading to higher operational...

This customer approached us looking for a solution for an indirect heating application. We designed, manufactured, installed and commissioned two large HET heaters. These units consist of a stainless steel concentric...

Our food and beverage customer approached us seeking support with reducing energy usage and downtime when a fault occurred. Their plant consisted of AHU and oven-base burners utilising both direct...

We are pleased to present another fantastic case study on a recent installation for a food industry application. After visiting the customer’s site, we concluded that the burners they need...

Comtherm’s customer, a manufacturer of glass coating machinery, took the advice of our Servicing Team to swap their current system to include a recuperator on the premises that would save...

In collaboration with our joint venture, Seibold + Comtherm, we recently completed a major burner upgrade for a client in the insulated fibre board manufacturing sector. The project involved the installation...

Our long-standing customer originally had a PH burner installed in 1995 for their drying application which was continually serviced until we recently suggested an upgrade for several efficiency benefits. Following...

Following a site visit to study this customers application, we decided to upgrade the current system to our 'PC' series. In line with the customers requirements, our direct replacement unit...

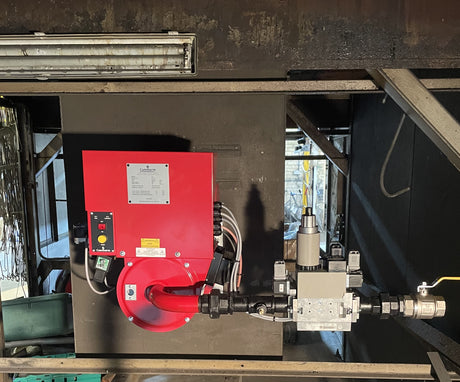

This powder oven business approached us with an old, worn-down burner they requested to be upgraded after noticing less effective drying. Due to the obsolete components, the customer was unable to acquire...

A long-standing industrial client required a significant upgrade to their heating system due to the deteriorating condition of their existing burner, which had become unreliable with obsolete components and a...

After 20 years of firing our reliable PC burner, our powder-coating customer decided it was time to invest in a brand-new burner to continue the job. The customer was pleased with the...

Our customer approached us about their industrial ovens at their automotive paint-drying plant. We were asked to replace their heat exchange system to support their aims to increase their energy...

A prominent player in the UK's ceiling tile manufacturing sought a comprehensive upgrade on the burner units for the heating of their new section of oven that would have a positive...

This customer approached us looking to develop an energy-efficient system for their waste management business. The bespoke combustion system that the customer wanted to achieve would use a pyrolysis method for heating...

This metal processing company contacted us to discuss their current system and explore the ways in which they could make improvements to meet the current environmental standards. Upon our visit, we...