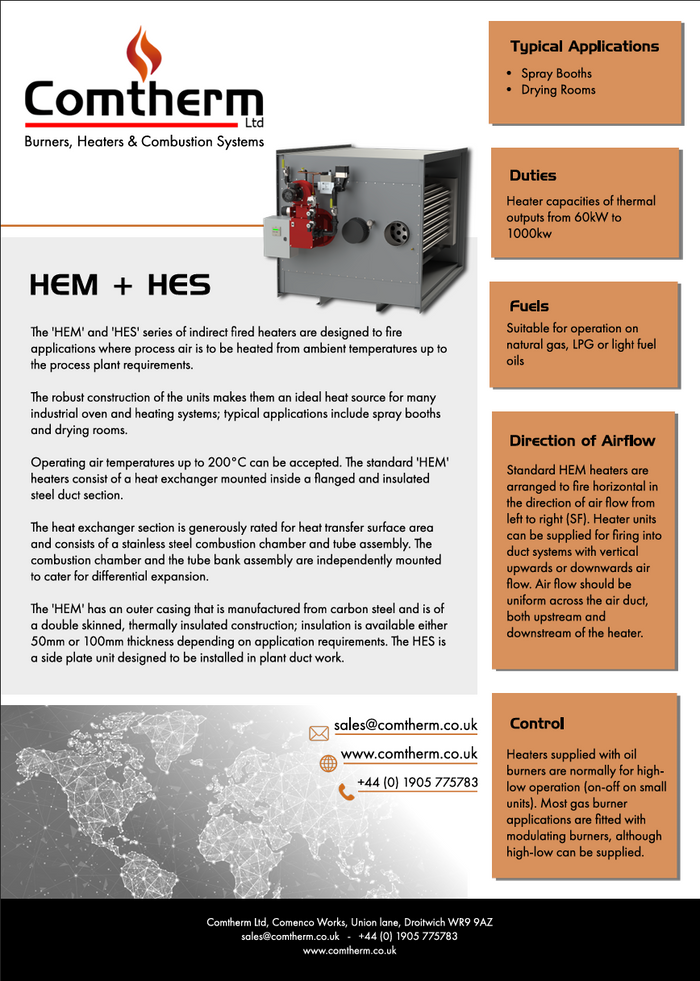

The ‘HEM’ series of indirect fired heaters are designed to fire applications where process air is to be heated from ambient temperatures up to the process plant requirements. The robust construction of the units makes them an ideal heat source for many industrial oven and heating systems; typical applications include spray booths and drying rooms. Operating air temperatures up to 300C can be accepted. The standard HEM heaters consist of a heat exchanger mounted inside a flanged and insulated steel duct section. The heat exchanger section is generously rated for heat transfer surface area and consists of a stainless steel combustion chamber and tube assembly. The combustion chamber and the tube bank assembly are independently mounted to cater for differential expansion. The outer casing of the HEM unit is manufactured from standard carbon steel and is of a double skinned, thermally insulated construction; insulation is available either 50mm or 100mm thickness depending on application requirements. The complete inner assembly can be withdrawn on its front plate for repair or servicing.

HEM Heater Technical Features

-

Typical Applications

-

Turndown

-

Burner Duty

-

Gas Supply Pressure

-

Fuel Types

-

Flame Length

mm (max)