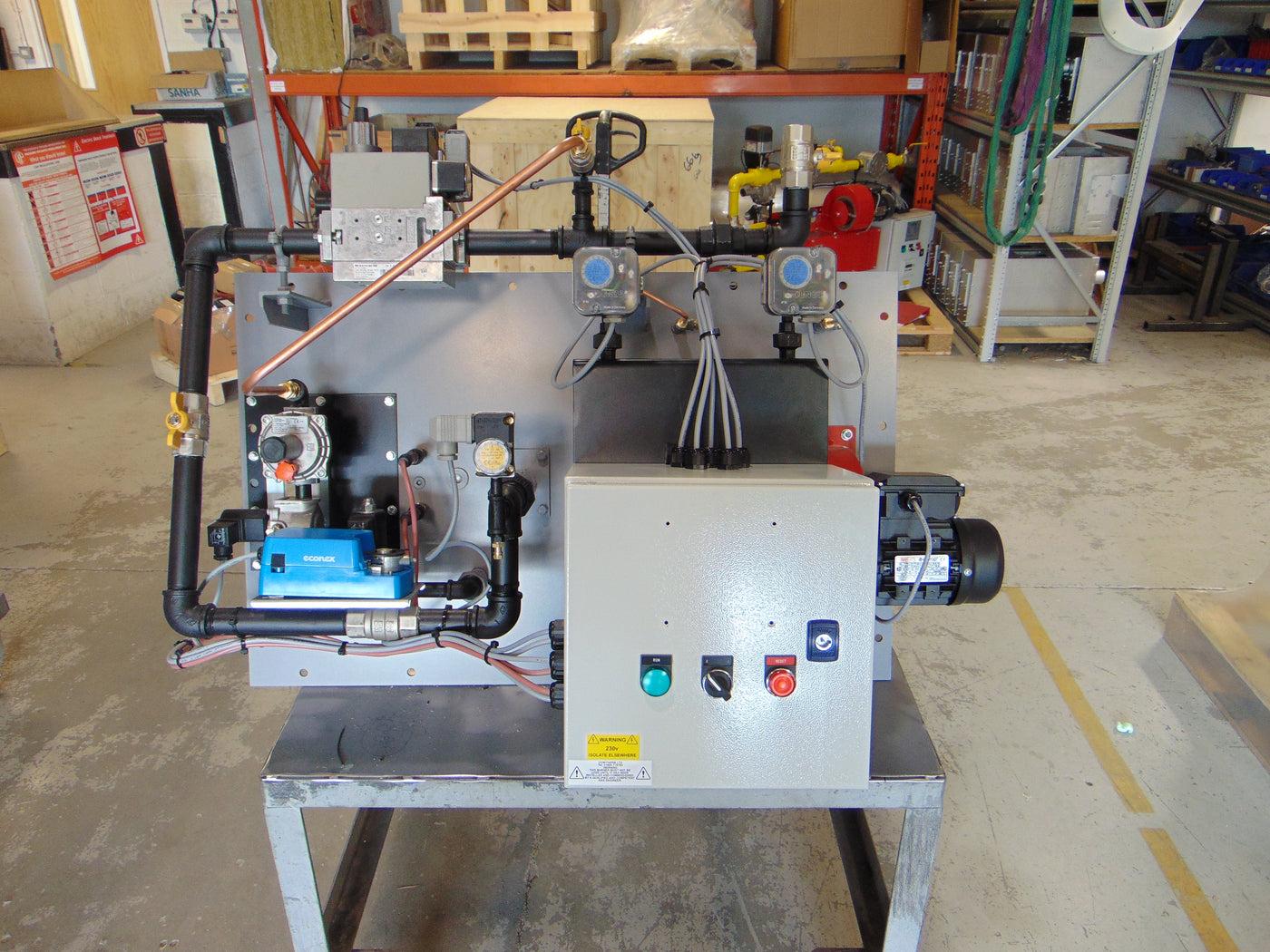

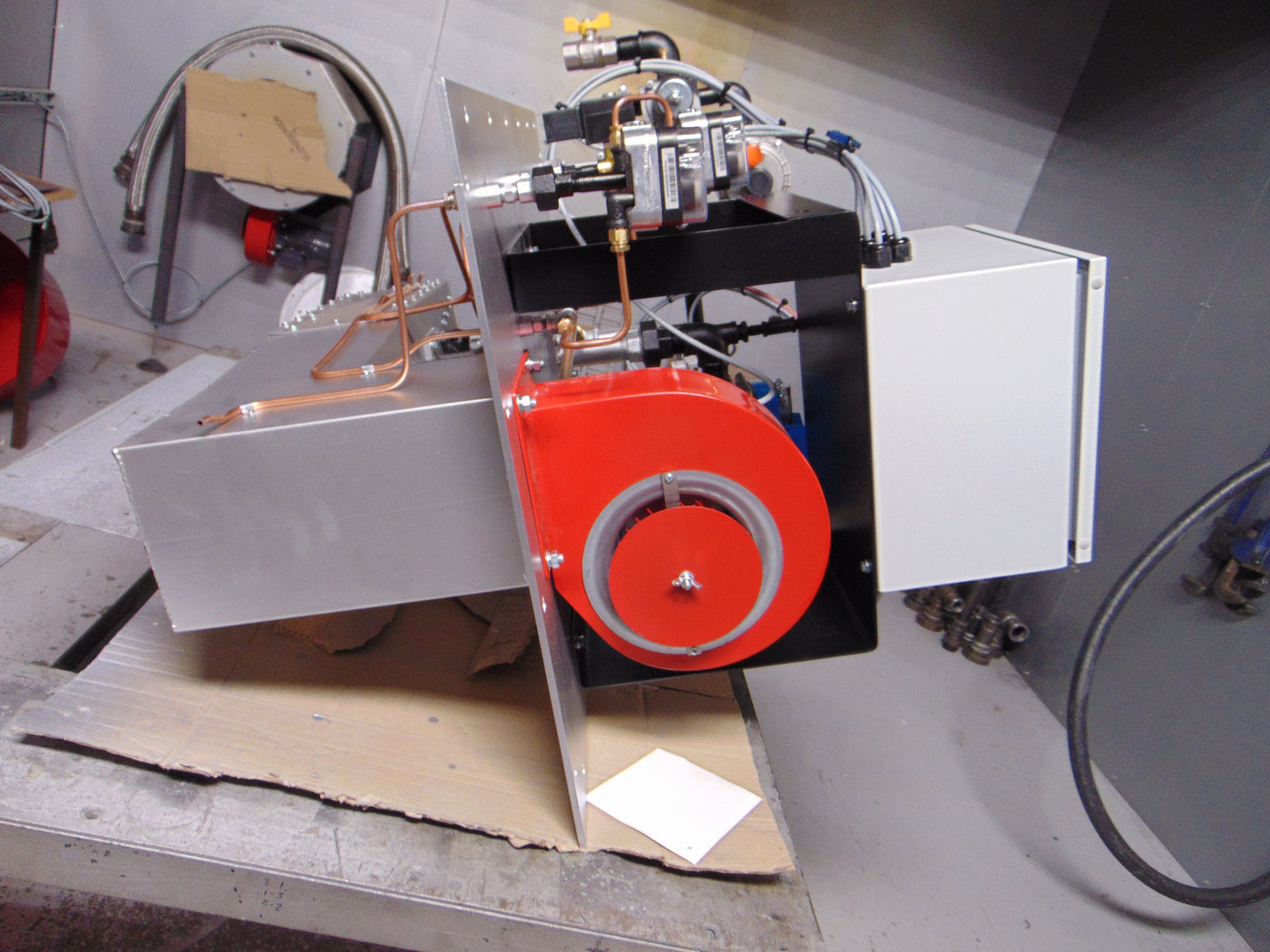

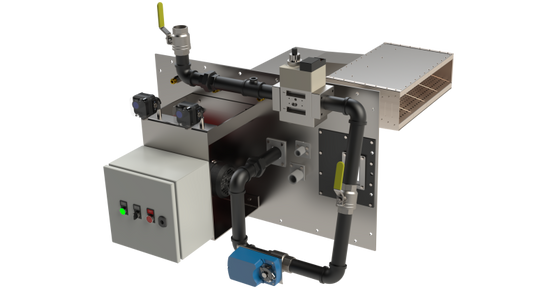

Bei den Gasbrennern der RSP-Serie handelt es sich um vorgefertigte, lüfterunterstützte Einheiten, die für nahezu alle Arten von gasbefeuerten Anwendungen geeignet sind, bei denen Umluft verwendet wird. Typische Anwendungen sind die Befeuerung von Industrieöfen und Trocknern. Der RSP kann in Prozessluftkanäle mit Luftgeschwindigkeiten von 5 bis 30 m/s eingebaut werden. Die Brenner können in ein Umluftsystem einer Prozessanlage eingebaut werden, in dem es nicht möglich ist, eine Brennkammer zu bauen und eine herkömmliche Brennerbaugruppe zu installieren. Die RSP-Brenner bestehen aus einem Inline-Verbrennungskopf vom Typ PH, der auf einer Seitenplatte montiert ist, sodass er parallel zur Seitenplatte in Richtung des Luftstroms brennt.

Die Einheiten sind in zwei Leistungsgrößen erhältlich; der Standard-RSP hat 300 kW pro 300 mm und der RSP-HC hat 600 kW pro 300 mm. Die Köpfe sind in den Abschnitten „gerade“, „T“ und „X“ erhältlich, sodass der Brenner so konstruiert werden kann, dass er zum Gerätelayout passt. Die gesamte für die Verbrennung erforderliche Luft wird von einem Verbrennungsluftgebläse geliefert, das an der Außenseite der Seitenplatte montiert ist – die Luft wird über einen integrierten Luftkanal zum Brennerkopf geleitet. Vor dem Brenner sind Prozesslufttemperaturen von bis zu 300 °C zulässig. Nach dem Brenner sollten die Temperaturen auf 450 °C begrenzt werden. Das Brennersystem erzeugt eine weite Flammenausbreitung und eine kurze Flamme; diese Eigenschaft macht den Brenner ideal für Anwendungen, bei denen die Kammerlänge begrenzt ist.

Der RSP-Brenner ist einfach und sicher zu bedienen. Alle Brenner werden vorgezündet und vollständig getestet, bevor sie unser Werk verlassen.

Technische Merkmale von RSP

-

Typische Anwendungen

-

Aufschlagen

Bis zu 40:1

-

Brennerleistung

-

Gasversorgungsdruck

Typischerweise 20 mbar.

-

Kraftstoffarten

-

Flammenlänge

600 mm (max.)

Downloads

-

RSP Brennerhandbuch

Laden Sie eine PDF-Kopie herunter, indem Sie auf den untenstehenden Link klicken.

-

RSP-Brenner Datenblatt

Laden Sie eine PDF-Kopie herunter, indem Sie auf den untenstehenden Link klicken.