The Siemens LMV (Linkage-less Burner Management System) is a sophisticated control system designed for managing and optimising the operation of industrial burners. Burner management systems are crucial components of industrial heating processes, ensuring the safe, reliable, and efficient combustion of fuels.

The primary functions of the Siemens LMV Burner Management System include:

Burner Control: The LMV system controls the operation of the burner, regulating the fuel and air supply to achieve the desired combustion conditions. It monitors and adjusts parameters such as fuel flow rate, air-to-fuel ratio, and flame stability to ensure efficient combustion.

Safety: Safety is a critical aspect of burner management systems. The LMV system incorporates multiple safety measures to prevent hazardous conditions, such as fuel leaks, flame failure, or excessive temperatures. It continuously monitors burner operations and initiates safety shutdowns in case of abnormal conditions or malfunctions to protect personnel and equipment.

Ignition Control: The system controls the ignition sequence, ensuring that the burner ignites reliably and in a controlled manner. It monitors the flame detection and provides feedback to verify successful ignition. In case of flame failure during operation, the system initiates appropriate safety measures.

Fuel and Air Optimization: The LMV system is designed to maximize combustion efficiency and minimize emissions. It optimizes the fuel and air mixture by continuously adjusting the burner parameters based on real-time measurements and process conditions. This optimization helps improve energy efficiency, reduce fuel consumption, and minimize environmental impact.

Diagnostic and Maintenance Support: The LMV system provides diagnostic capabilities and maintenance support, allowing operators to monitor and troubleshoot burner performance. It offers real-time data on burner operations, alarms, and system health, helping operators identify potential issues and plan maintenance activities proactively.

Integration and Communication: The LMV system can be integrated into larger industrial automation systems, allowing seamless communication with other control systems and providing data exchange for process optimization and monitoring. It supports various communication protocols to ensure compatibility with different plant architectures.

The Siemens LMV Burner Management System combines advanced control algorithms, safety features, and diagnostic capabilities to ensure safe and efficient burner operation in industrial heating applications.

Most LMV controls are designed to work with the SQM3 and SQM1 range of actuators. When combined, this ensures accurate positioning of the air and fuel dampers, thus ensuring the optimum combustion with the lowest possible emissions. Variable actuator running times provide for a faster startup when the ‘call for heat’ is registered.

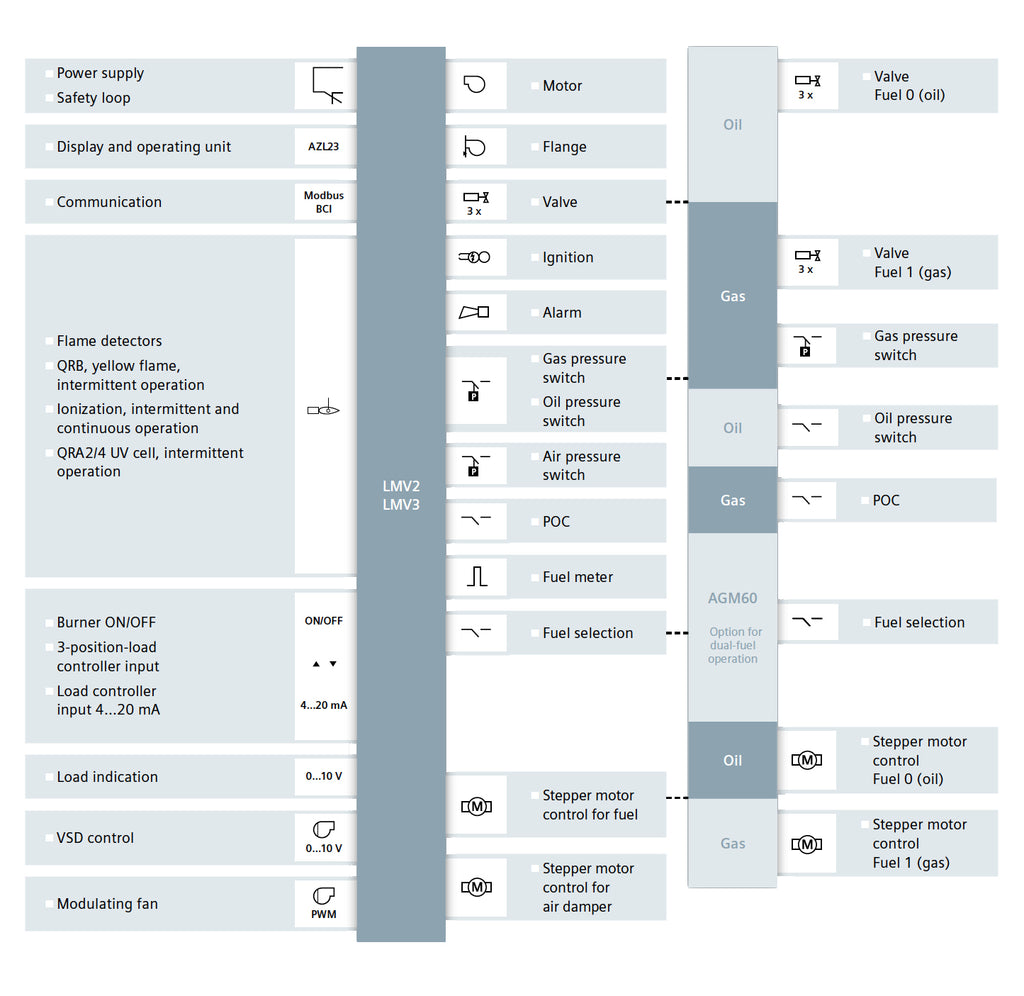

The main benefit of selecting an LMV as part of your burner controls is the simplified design of the overall burner management system. The LMV2 or LMV3 controllers both include burner control, ratio control and gas proving as standard.

Depending on the Siemens LMV selected, the units include built-in variable program sequences for the control of your burner. There is a choice of Gas or Oil programs, with or without a pilot burner. When used with the AGM60 change-over unit, dual fuel applications are possible.

For even faster commissioning, the gas valve proving can be optionally activated during the post-purge phase. Single actuator setup can also be set up for pneumatic air-fuel ratio control.

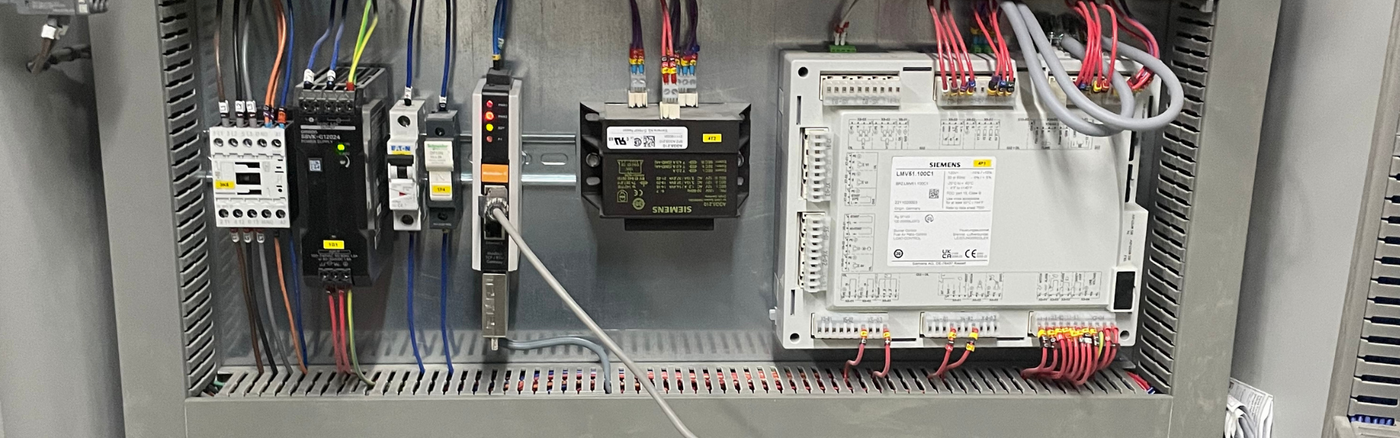

The LMV3 is approved for continuous operation with ionisation probes, enabling it to be used in steam boiler applications or in process heat applications. The LMV2 and the LMV3 units are designed to be mounted on the burner itself or in a control panel adjacent to the burner components.

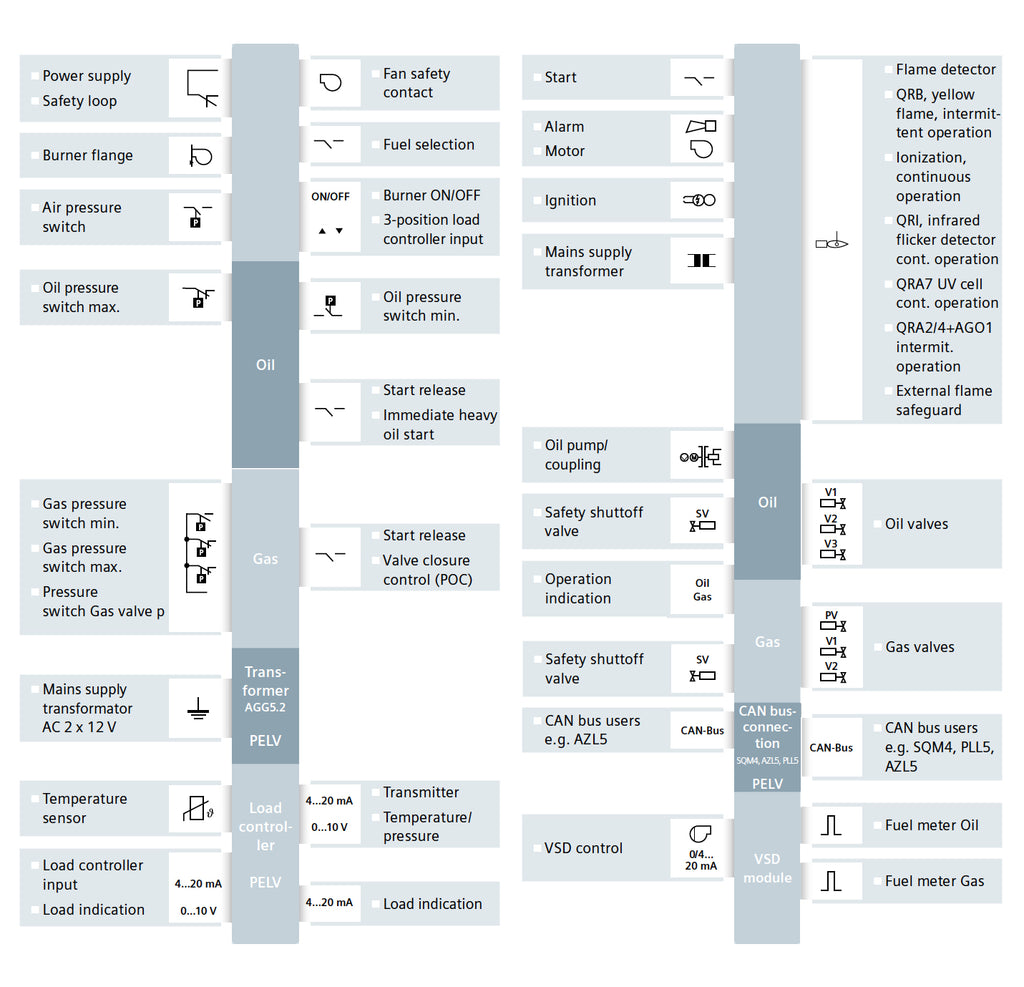

Features on the LMV5 controllers are similar to the LMV3 but with additional benefits

and options. When equipped with a Siemens LMV5-based combustion control, the system can be equipped with a load controller, VSD control and O2 combustion optimisation. The load controller features an electronic safety limit thermostat. The Siemens LMV52.4 model also offers a temperature-compensated flue gas recirculation function for “super” low NOx applications, along with specific O2 control functions for fibre mesh burners.

On the LMV5 controls, the optional integrated load control is in the form of a PID temperature/ pressure controller featuring an algorithm for the cold startup process of hot water or steam boilers, thus ensuring lower wear and tear.

The LMV5 controllers are suited to continuous operation when used with a UV IR Flame Detector or an ionisation probe. The system utilises a CANBUS interface allowing for multiple actuators to be placed throughout the burner for process applications where zoning is required or where seasonal changes need to be catered for. Due to the internal screening of the CANBUS cable, there is no limit on cable lengths used when using this system.

Separate inputs and outputs for oil or gas-fired operation deliver accurate diagnostics for each of the connected components and also allow for dual-fuel operation with no need for additional relay changeover.

Siemens LMV3 Details

Siemens LMV5 Details